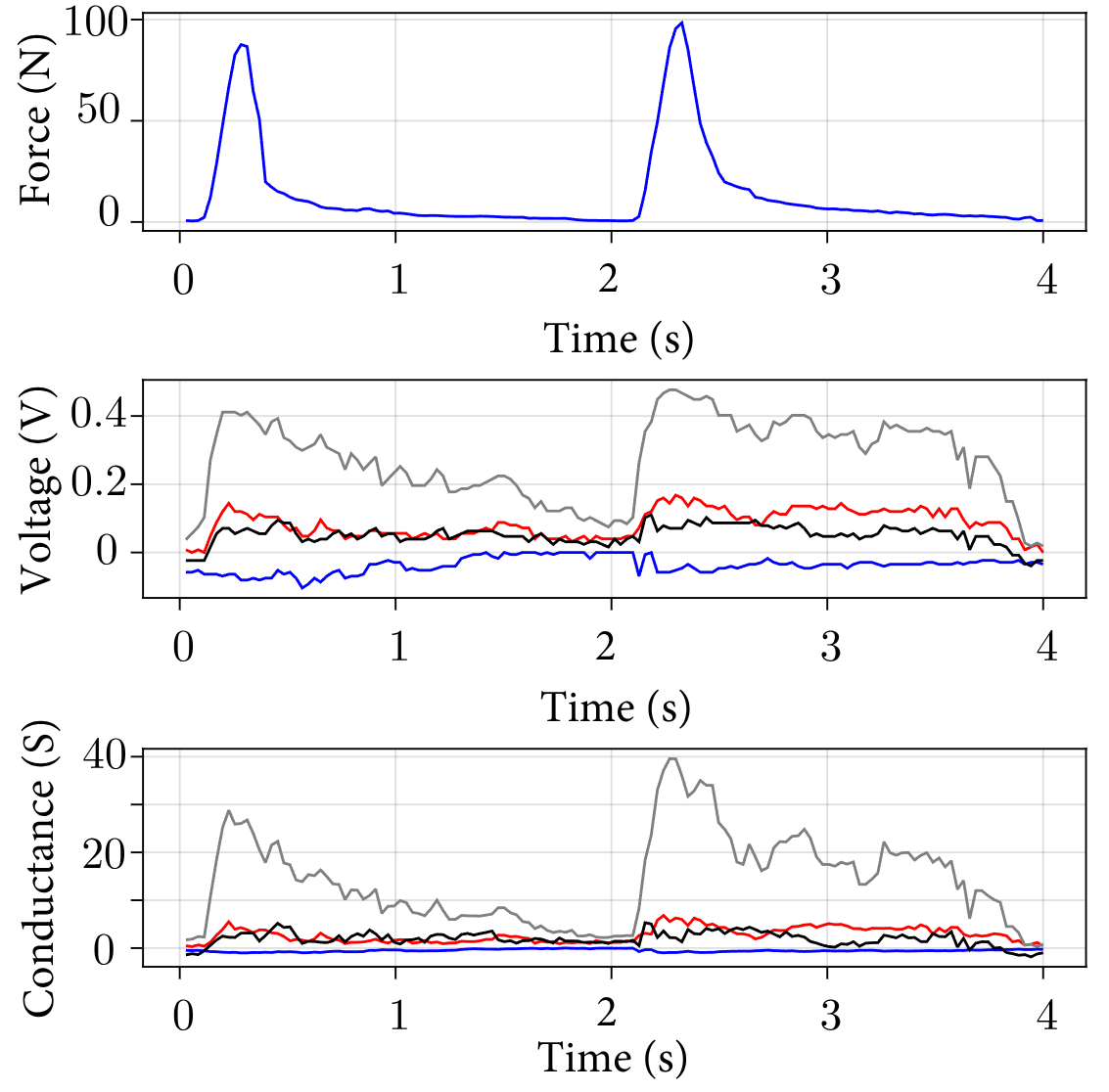

Tactile and textile skin technologies have become increasingly important for enhancing human-robot interaction and allowing robots to adapt to different environments. Despite notable advancements, there are ongoing challenges in skin signal processing, particularly in achieving both accuracy and speed in dynamic touch sensing.

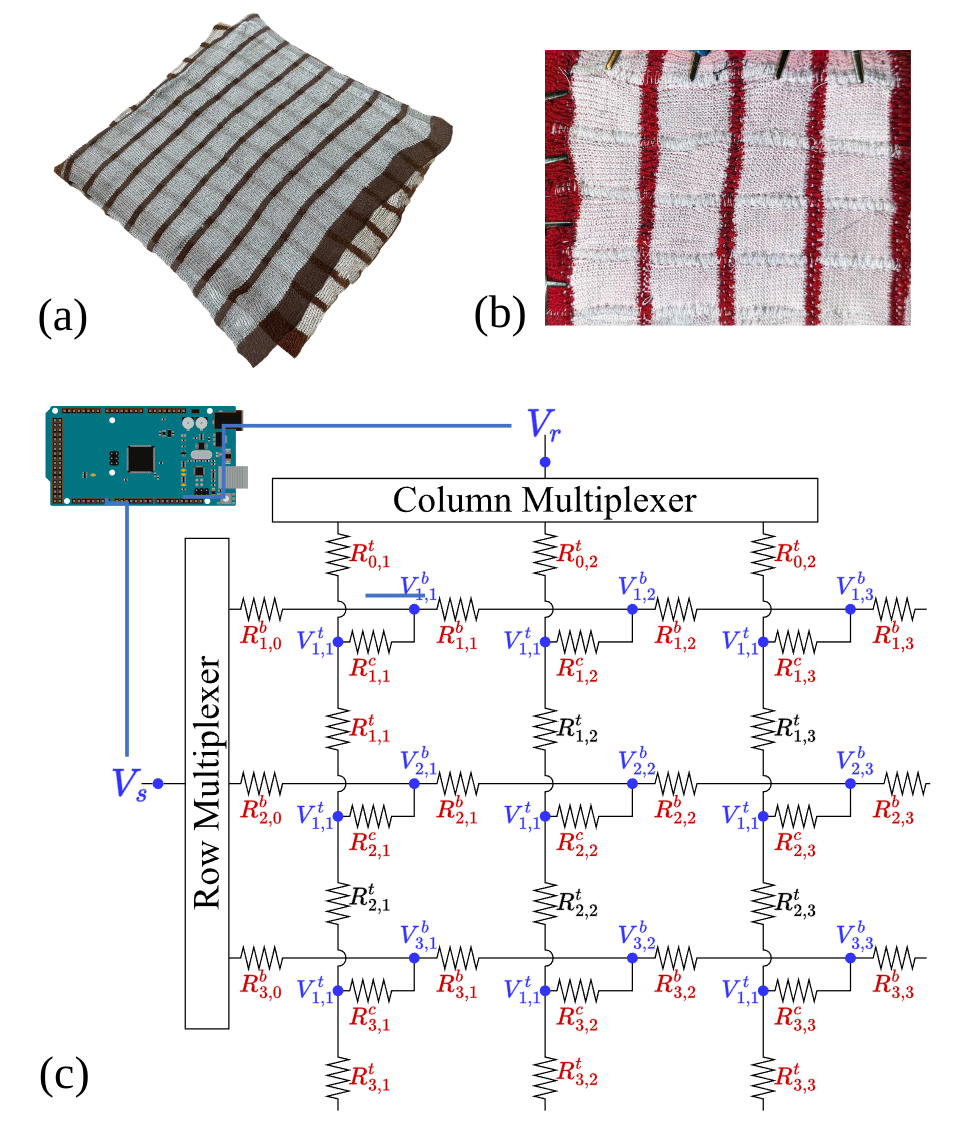

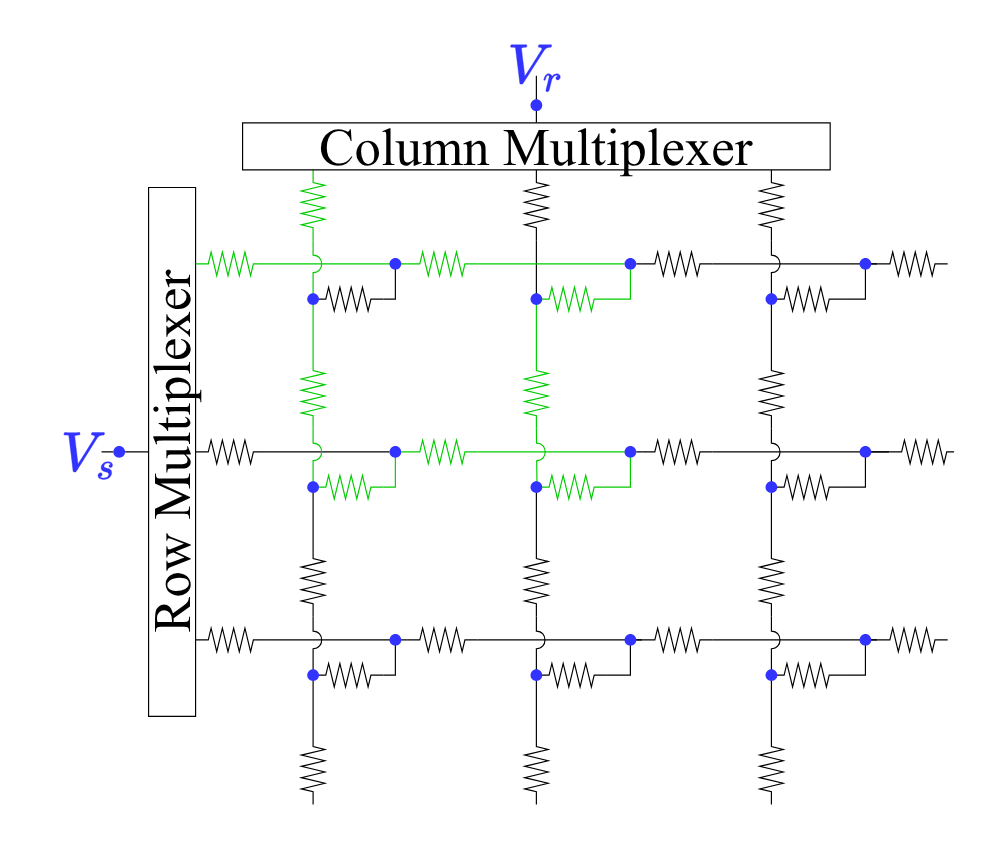

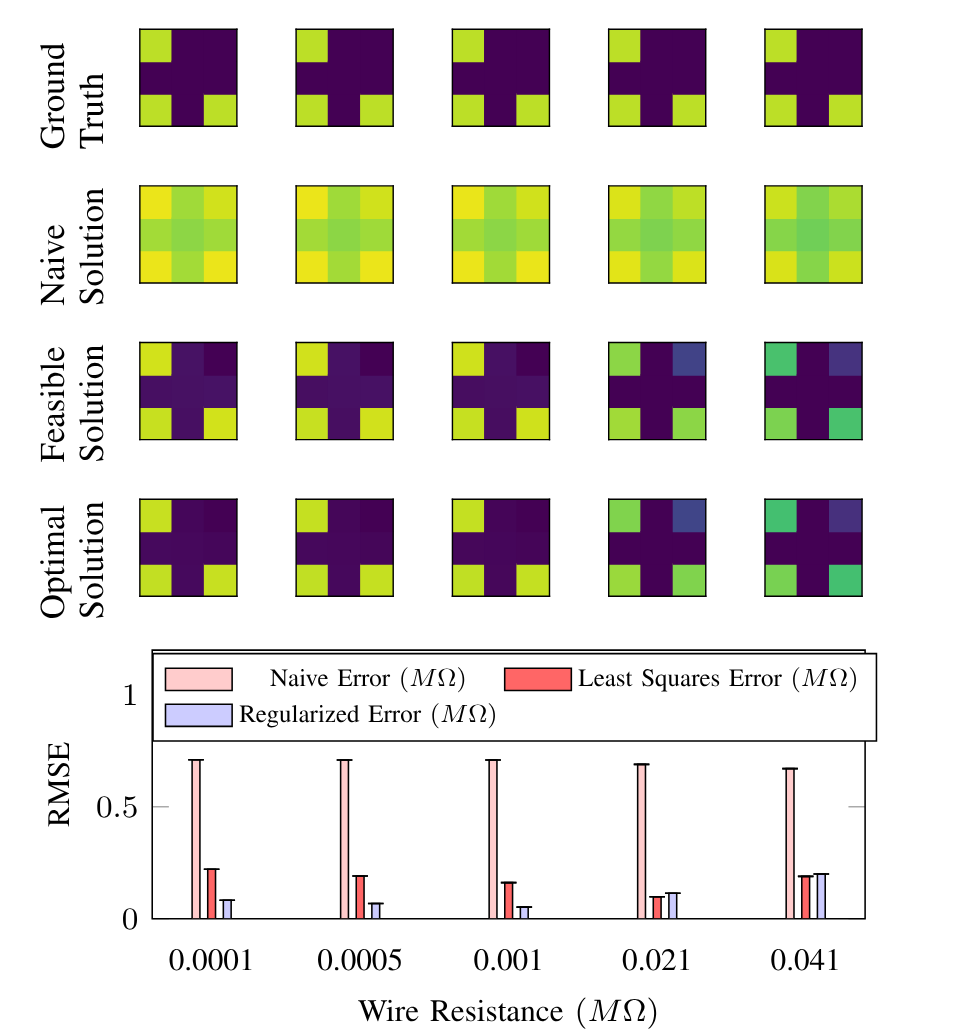

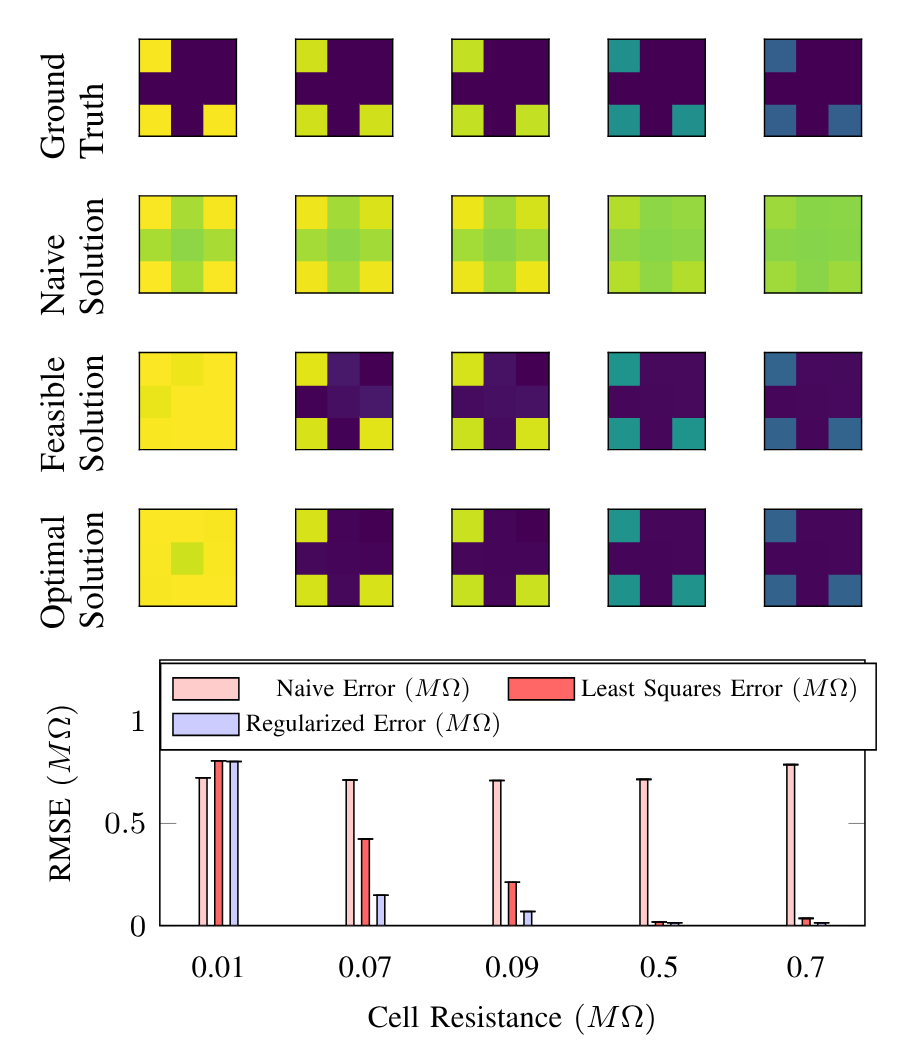

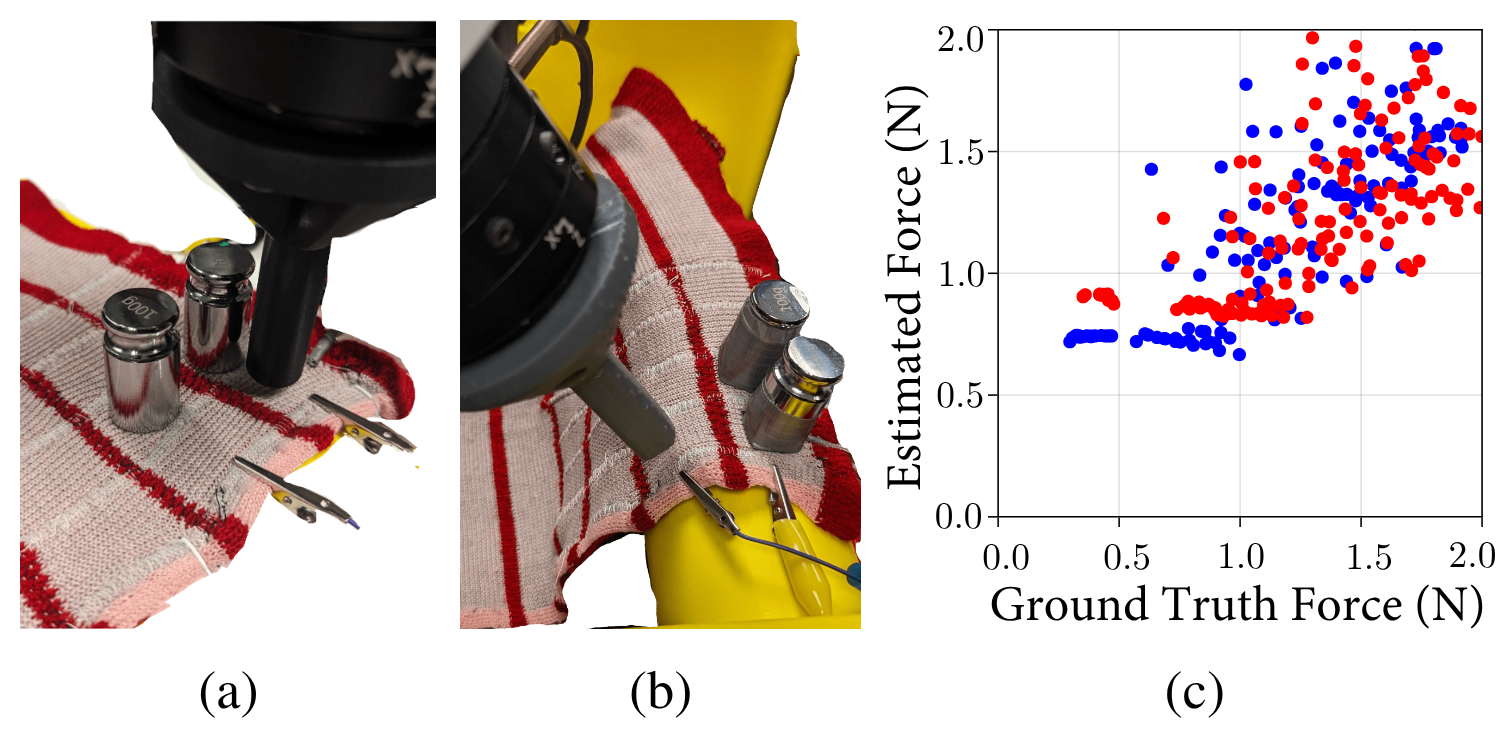

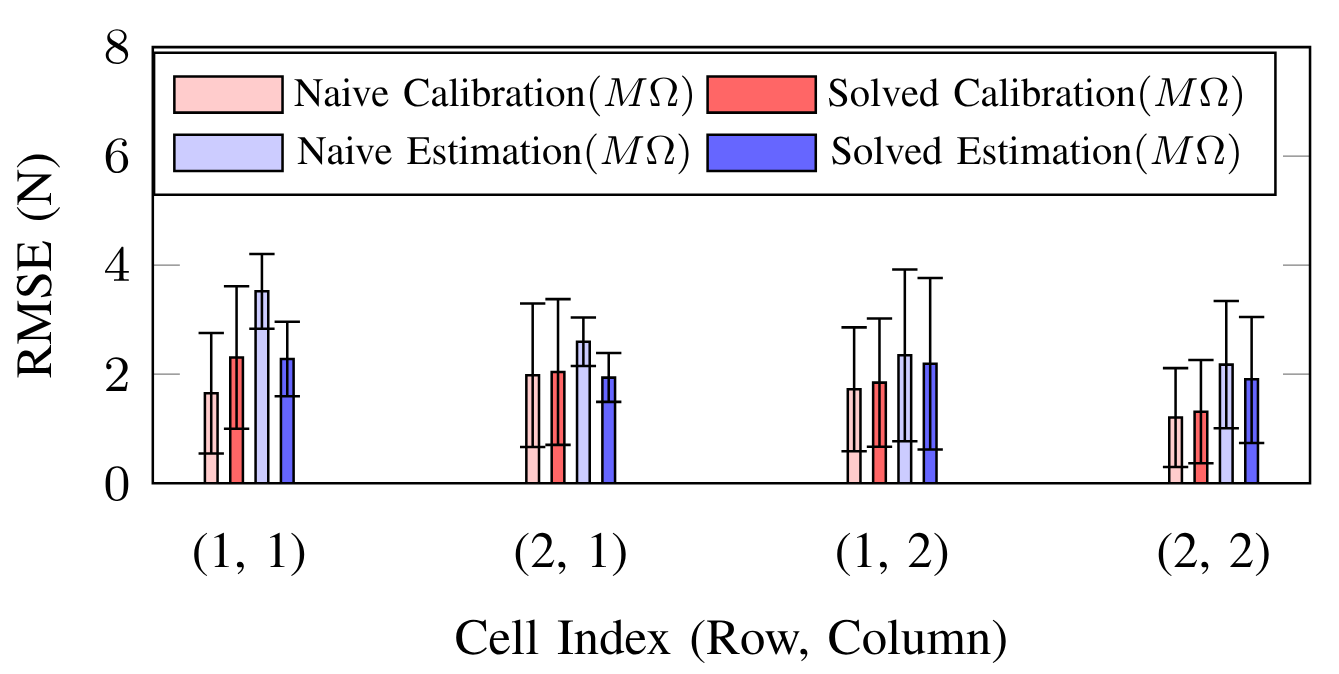

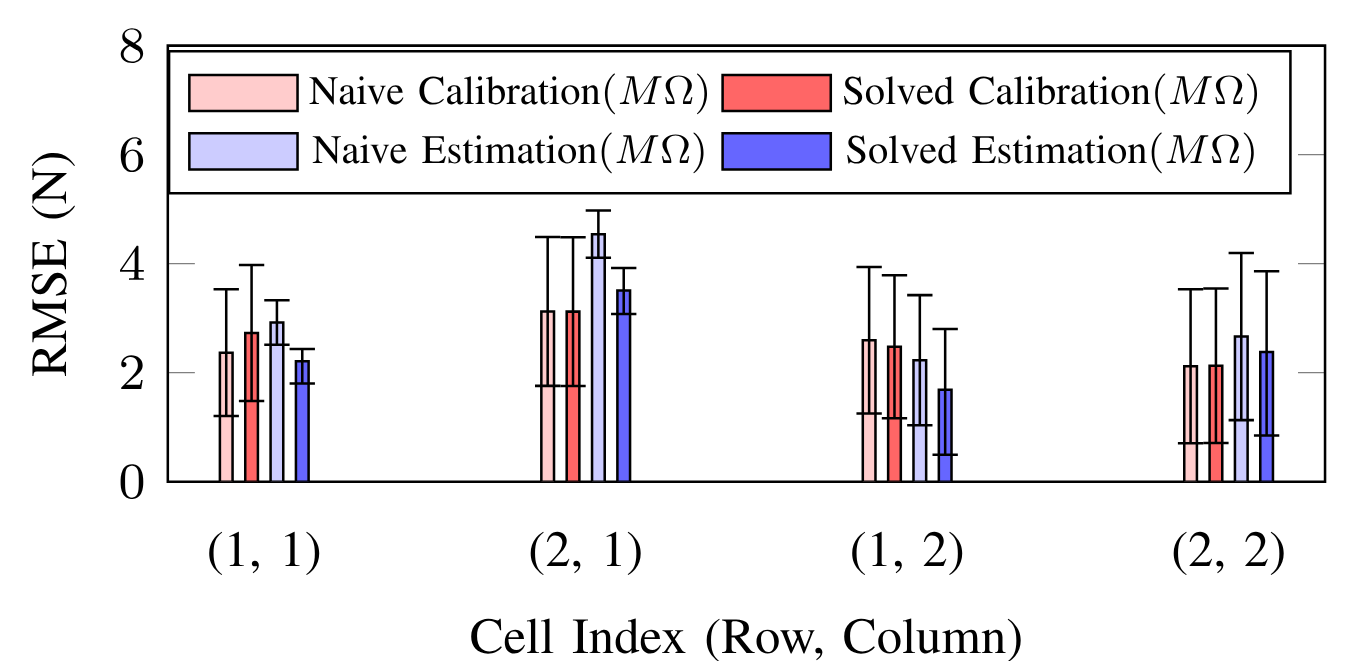

This paper introduces a new framework that poses the touch sensing problem as an estimation problem of resistive sensory arrays. Utilizing a Regularized Least Squares objective function—which estimates the resistance distribution of the skin—we enhance the touch sensing accuracy and mitigate the ghosting effects, where false or misleading touches may be registered. Furthermore, our study presents a streamlined skin design that simplifies manufacturing processes without sacrificing performance. Experimental outcomes substantiate the effectiveness of our method, showing 26.9% improvement in multi-touch force-sensing accuracy for the tactile skin.